Advanced Coating & Laminating

J-LITE’s functional coating and laminating technologies enhance product lifespan, hygiene, and durability by adding various performance features tailored to material properties and end-use requirements.

Our coatings offer a wide range of functions, including waterproofing, water repellency, antibacterial protection, flame retardancy, and UV blocking—maintaining reliable protection even against heat, moisture, and friction. Designed for processability and consistent quality, these technologies deliver high-performance surface treatment solutions for applications in apparel, industrial fabrics, hygiene materials, and composite films.

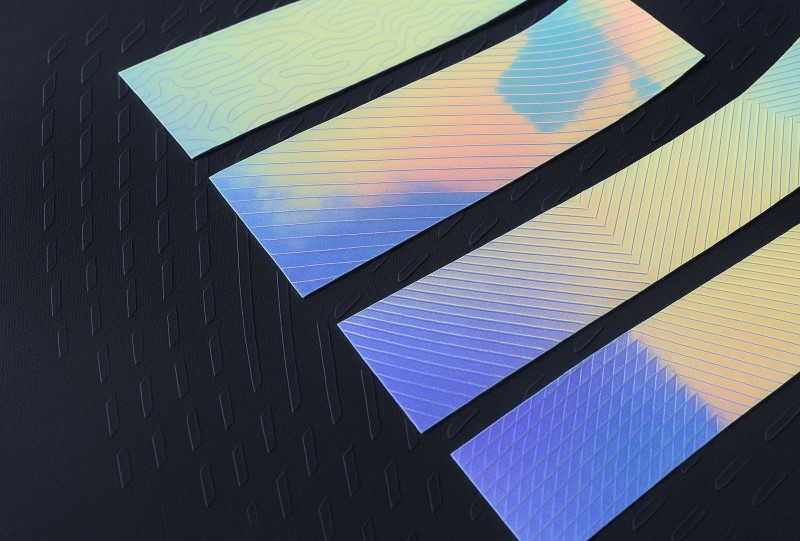

Bringing Sensory Appeal and Precision to Every Surface.

J-LITE pushes the boundaries of surface technology, delivering advanced finishing solutions that combine protection, aesthetics, functionality, and post-processing stability in perfect balance.

We go beyond basic protection to focus on sensory qualities such as texture, gloss, and adhesion. Our flexible material designs balance functionality with aesthetics, ensuring uniform coating distribution, stable bonding between laminate layers, and smooth performance in printing, cutting, and post-processing.

This approach goes beyond material production to offer strategic finishing solutions that enhance both design precision and manufacturing efficiency. At J-LITE, our finishing technologies help bring your brand’s intended impression to life—right from the surface of the material. It is the result of a comprehensive quality design that considers not only product appearance, but also the environment in which it is used, the user’s experience, and long-term maintenance.

STRUCTURAL VISION

Surface design is not just about adding functionality. At J-LITE, we consider the user environment and experience, offering structural solutions through precisely engineered technologies that control coating texture, adhesion, and interlayer performance.

Refined Finish That Shines Even on Curved Surfaces

J-LITE’s functional coating technology ensures uniform coating thickness and precise adhesion not only on flat surfaces, but also on curves and three-dimensional structures.

Even after cutting, sewing, or laminating processes, the texture and sheen of the surface remain smooth and consistent, delivering a refined finish in both appearance and touch.

Unshaken Stability Under External Stress

J-LITE’s functional coatings are engineered to resist a wide range of environmental stressors—including heat, humidity, dust, friction, and detergents. They maintain their original texture and performance even through repeated washing and exposure to high heat and pressure, delivering reliable durability across diverse applications such as apparel, industrial materials, and medical textiles.

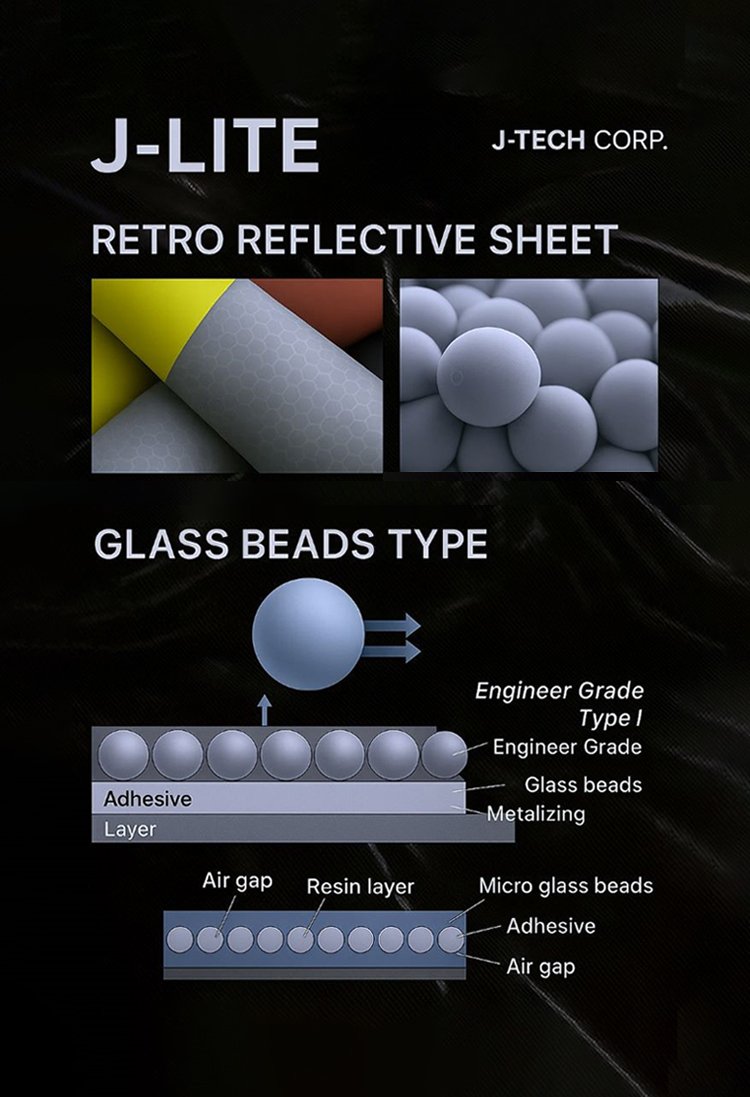

A single beam of light can illuminate the path, and a sharp reflection can save a life.

Revealing dangers hidden in the dark—that is the essence of reflective sheets, and the reason we do what we do.

Safety sometimes begins with the smallest, quietest glimmer.

Like a trace of light that never fades in the dark, our technology detects unseen dangers in advance—protecting someone’s day with a single reflected light.

Light may pass in a moment, but the trust we build lasts.

Ensuring quality even in the unseen moments—that’s why we are committed to perfecting our reflective fabrics.

Stable Lamination for Composite Materials

J-LITE offers coating and laminating solutions that are compatible with a wide range of textile and non-textile materials, ensuring optimal performance tailored to specific processing conditions.

J-LITE’s solutions ensure stable lamination not only on apparel textiles such as cotton, polyester, and nylon, but also on non-fabric materials like foam, film, and metal sheets. Our technologies are compatible with various manufacturing processes, including roll-to-roll, heat pressing, and laminating, enhancing both productivity and post-processing efficiency in high-performance finishing. This expands design flexibility and supports a wider range of real-world applications across different production environments.